Ever stood in awe of a perfectly crafted box, curious about the machinery behind its creation? In the sprawling ecosystem of manufacturing, there emerges a quest for the ideal apparatus to craft flawless packaging.

Delving into this world, I discovered that the box machine, often overlooked, is truly the linchpin in the seamless production of boxes, marrying both art and precision.

In this article, we journey together into the heart of box machine operations. From their intricate mechanisms to diverse applications, we offer a deep dive into understanding and appreciating their nuances.

Ready to uncover the secrets? Let’s embark.

1. The Basics of Box Machines

A box machine is a mechanical device specifically designed to manufacture boxes in various shapes and sizes. These machines perform a series of operations like cutting, creasing, folding, and gluing to convert flat sheets of material, such as cardboard or corrugated board, into boxes. Having spent a fair share of my career in this industry, I can confidently affirm that these machines are the cornerstone of the packaging world.

Box machines, crucial for meeting rising demands in sectors like retail, food, and electronics, hold the key to business competitiveness today. As the global packaging market, according to Smithers, is expected to hit $1.05 trillion by 2024, businesses utilizing box machines stand a better chance to thrive. Effective packaging production boosts competitiveness. Hence, investing in advanced box machines is key to long-term success.

2. The Impact of Box Machines on Business Operations

Understanding the impact of box machines on business operations is vital for strategic decision-making. Below, we delve into some critical areas:

Cost-Effectiveness

Box machines, by introducing automation, revolutionize production, lowering costs, and enhancing operational efficiency through reduced reliance on manual labor. These machines ensure the resourceful use of raw materials, minimizing waste, driving cost savings, and promoting environmental sustainability. As a long-time industry observer, I’ve seen companies transform financially with the strategic use of box machines.

Speed of Production

Box machines’ rapid production rates, generating hundreds to thousands of boxes per hour, vastly outpace manual processes, significantly boosting productivity. This exceptional speed enables businesses to adeptly meet peak demand, guaranteeing consistent supply. Observing industry trends over the years, I’ve witnessed how the speed facilitated by box machines has not just improved but revolutionized the box-making industry.

Customization Capabilities

Box machines offer the ability to produce boxes of varying sizes and designs, allowing businesses to customize their packaging based on specific needs. This flexibility is paramount in today’s market, where customization is often equated with customer satisfaction. Moreover, with Autoboxup’s advanced machines, businesses can ensure precision and consistency in their custom designs.

This table is a conceptual representation based on the information provided and does not reflect actual data or specific metrics. It’s intended to illustrate the customization capabilities of Autoboxup’s box machines.

| Customization Capabilities |

Description |

| Varying Sizes |

Autoboxup’s box machines can produce boxes in a wide range of sizes, accommodating the specific dimensions required by different products and packaging needs. |

| Design Flexibility |

The machines offer businesses the freedom to create custom box designs, including shapes, cutouts, and graphics, enabling unique and eye-catching packaging solutions. |

| Tailored Packaging |

Businesses can customize packaging to align with their brand identity, enhancing recognition and creating a memorable unboxing experience for customers. |

| Personalization Options |

Autoboxup’s machines allow for personalized printing, enabling businesses to add logos, text, barcodes, and other elements to make each box distinctive. |

| Market Responsiveness |

The ability to rapidly adjust box sizes and designs empowers businesses to respond quickly to market trends, promotions, or seasonal changes, staying competitive. |

| Enhanced Customer Satisfaction |

Customized packaging reflects a commitment to customer preferences, enhancing satisfaction and building a stronger connection between businesses and consumers. |

| Precision and Consistency |

Autoboxup’s advanced technology ensures precise and consistent production of custom designs, minimizing variations and maintaining high-quality packaging standards. |

| Efficiency and Automation |

The automated process of creating custom boxes reduces manual labor, increases production efficiency, and minimizes errors, contributing to cost savings. |

3. Different Types of Box Machines

Box machines come in various types, each tailored to a specific material and design requirement. Let’s delve into three main types:

Corrugated Box Machines

Corrugated box machines produce sturdy and durable boxes, perfect for shipping or handling heavy items. These machines mold corrugated boards into the desired shape and size, ensuring high structural integrity. Having seen their impact first-hand, these machines are critical for businesses needing robust packaging solutions.

Cardboard Box Machines

Cardboard box machines present a versatile avenue for businesses seeking resilient, yet lightweight packaging. They’re perfect for crafting boxes for consumer items, from food products to small gadgets. For example, the machine’s meticulous cutting accuracy and consistent creasing play pivotal roles in determining the end product’s impeccable quality.

Rigid Box Machines

Rigid box machines craft premium boxes with exceptional detail and finish, elevating the prestige of luxury items or gifts. From my observations, businesses that prioritize quality in their packaging tend to create a more memorable unboxing experience, enhancing their brand image in the process. Leveraging equipment from reputable manufacturers, businesses can guarantee unparalleled packaging excellence consistently.

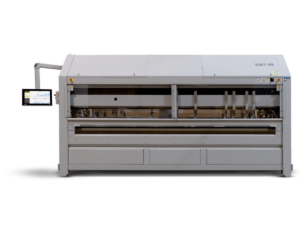

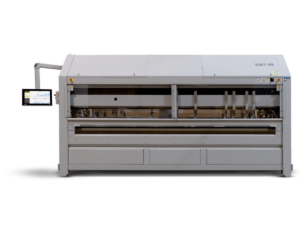

4. Component Parts of a Box Machine

A box machine is a complex assembly of different components, each playing a critical role in the box-making process. Let’s delve into the four main sections of a box machine:

Paper Feed System

The paper feed system is where the box-making process begins. It draws the raw material into the machine for further processing. An efficient paper feed system ensures steady, uninterrupted operation and plays a critical role in maintaining production speed. Remember, a well-maintained feed system can significantly reduce downtime and enhance overall productivity.

Cutting and Creasing Mechanism

The cutting and creasing mechanism is responsible for giving the box its shape. Precision and consistency are the hallmarks of a good cutting and creasing mechanism. In my years of experience, I’ve seen how a well-calibrated cutting and creasing mechanism can significantly improve the final product’s aesthetics and functionality.

Gluing and Folding Section

The gluing and folding section is where the box starts to take its final form. This section applies adhesive to the box and folds it into its final shape. The efficiency of this stage is vital for the box’s durability, enabling it to endure the demands of transport and handling. For instance, the application of the adhesive needs to be uniform across all contact points to ensure maximum hold and prevent the box from falling apart under stress.

Stacking and Output Area

The stacking and output area is the final section of the box machine. Here, the finished boxes are neatly stacked, ready for further packaging or immediate use. A well-organized output area streamlines the process, reducing the risk of damage to the finished boxes. It’s the final step in the box-making journey, ensuring that the finished product is ready to serve its purpose.

5. Box Machine Applications

Box machines have a broad spectrum of applications across various industries. Let’s take a closer look at three key sectors that heavily rely on these machines:

Packaging Industry

Box machines are central to the functioning of the packaging industry. They facilitate the manufacture of custom packaging that protects the product and simultaneously serves as a marketing tool, communicating the brand’s ethos to the consumers. Every packaged product, from food and beverages to pharmaceuticals, often has a box machine to thank for its tailored casing.

Warehousing and Logistics

Box machines hold significant importance in the warehousing and logistics industry, where they contribute to the creation of robust shipping containers. The efficient use of box machines allows for the manufacture of custom-sized boxes, which results in optimal space utilization. These custom boxes also enable safer and more efficient transportation of goods, highlighting the critical role of box machines in this sector.

Retail Businesses

In the retail sector, box machines have a multifaceted role. They aid in creating boxes of diverse sizes, suitable for various products, while their customization capability enhances retail businesses’ product appeal and branding. Speaking from personal experience, this flexibility in design and size is an invaluable asset for any retail business looking to create a unique and impactful customer experience.

6. Box Printing Technologies

Beyond box shaping, printing plays a vital role, in introducing branding, instructions, and visual appeal to the box. Drawing from years of observation, the right printing method can truly uplift the packaging’s overall impact. Now, let’s explore the varied Box Printing Technologies in use today:

Flexographic Printing

According to PLCTX, Flexography often referred to as flexographic printing or flexo printing uses a flexible relief plate made from soft plastic, rubber, and UV polymer. These plates feature a raised image of the design to be printed. This printing method is ideal for packaging due to its ability to work with a wide range of substrates and its cost-effectiveness in the long run.

Lithographic Printing

Also known as litho or offset printing, lithographic printing offers high-quality, detailed prints. This method is based on the principle that water and oil do not mix. It involves the application of ink to selected areas of a plate, which are then offset onto a rubber blanket and subsequently onto the substrate. For instance, businesses looking for premium packaging with high-quality imagery often resort to lithographic printing.

Digital Printing

Digital printing, a cutting-edge addition to the printing domain, offers groundbreaking benefits. It simplifies the process by eliminating plates or cylinders, and directly printing on the substrate. With its efficiency in reducing setup time and costs, it’s ideal for custom jobs. From my experience, digital printing has undoubtedly transformed the packaging industry, paving the way for unlimited innovation and creativity.

7. Key Features to Look for in a Box Machine

The box-making industry, with its continuous evolution, brings forth machines equipped with cutting-edge features. When considering an investment in a box machine, pay close attention to these vital features:

Speed and Efficiency

A primary consideration is the machine’s speed and efficiency. The faster a machine can produce boxes, the higher the potential output and profit. But it’s not just about speed; the efficiency in material use and minimal wastage are just as crucial.

Box Size Versatility

The capacity to create boxes of diverse sizes using just one machine is indeed a game-changer. This multifunctionality eliminates the requirement for multiple machines, streamlining production and bringing an unparalleled level of flexibility to your operations. In my experience, versatility is often a game-changer for businesses that cater to a diverse clientele.

User-friendly Operations

The user-friendliness of a machine is often overlooked, yet it plays a vital role in streamlining operations. Machines with intuitive controls and straightforward operation can drastically reduce the learning curve, enabling swift adaptation and minimizing downtime. This aspect should not be underestimated, as it directly impacts productivity and efficiency in the long run.

Safety Features

Safety is of utmost importance, and when it comes to box machines, it should never be compromised. Equip box machines with in-built safety measures like emergency stops and protective guards to ensure operator safety and prevent accidents. At Autoboxup, we take operator safety seriously and ensure that our machines are designed and manufactured with top-notch safety features to create a secure working environment.

Energy Efficiency

In an era where sustainability takes center stage, opting for energy-efficient machines not only leads to reduced operational costs but also aligns with a company’s commitment to eco-friendly practices. By investing in such machines, businesses demonstrate their dedication to responsible and environmentally conscious operations.

8. Selecting the Right Box Machine for Your Business

Purchasing a box machine involves more than addressing immediate needs; it requires considering the long-term benefits and alignment with business goals. Here, we provide guidance on essential considerations:

Assessing Your Needs

Before delving into models and specifications, businesses should have a clear understanding of their needs. Factors like the volume of boxes needed, types of boxes, and desired production speed should guide the selection process.

Evaluating Different Models

Once needs are mapped out, the next step is to evaluate the various models available. From my experience, considering factors such as machine durability, brand reputation, after-sales support, and technological features play a crucial role in making an informed decision. Additionally, seeking feedback from other businesses who have used similar machines can provide valuable insights.

Considering Your Budget

Personally, I find that budget considerations are crucial when investing in a box making machine. While it’s essential to invest in a quality machine, it’s equally vital to ensure it aligns with financial capacities and promises a reasonable return on investment. A well-thought-out investment in a box machine can lead to enhanced efficiency and profitability for the business.

Conclusion

In conclusion, box machines, though often overlooked, are central to the operations of various industries. They represent a blend of engineering and artistry, transforming raw materials into functional and visually appealing boxes. Companies with a commitment to quality and innovation, play a significant role in advancing this field, ensuring that the humble box continues to be an integral part of our everyday life.

To navigate this intricate landscape and make informed decisions, one needs a trusted partner. As someone who has seen the impact of Autoboxup’s cutting-edge machines firsthand, I can vouch for their expertise and commitment to excellence. Contact us and let Autoboxup, a pioneering manufacturer, be your guide in this box-making journey.