If you’re in the market for a V grooving machine, chances are you’ve got some cardboard projects in mind.

Whether you’re looking to make custom boxes or create intricate designs, a V grooving machine can help you take your projects to the next level. But with so many different machines on the market, how do you know which one is right for you?

In this buying guide, we’ll take a look at the best V grooving machines for cardboard and help you choose the one that’s perfect for your needs.

1. What Is a V Grooving Machine and Its Features?

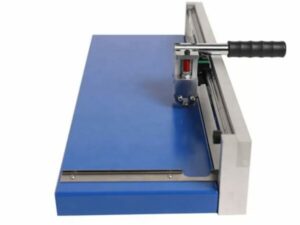

A V grooving machine is a type of CNC router that is typically used for cutting V-shaped grooves into the cardboard. These machines are often used in the packaging industry for die-cutting and score V-notches.

V grooving machines can also be used to cut V-shaped channels into other materials such as plastic, wood, and metal. There are many different types of V grooving machines on the market, each with its unique features and capabilities.

Some common features of V grooving machines include:

- The ability to cut V-shaped channels of varying depth and width

- A variety of cutting tools can be swapped out depending on the material being cut

- Powerful motors that provide high speed and accuracy

- Robust construction that can handle heavy-duty applications

2. Components of V Grooving Machine and Their Usage

A V grooving machine is a versatile tool that can be used for a variety of applications, from creating v-shaped grooves in wood to engraving text and patterns into metal. The machine consists of three main components: the V-bit, the spindle, and the table.

- The V-bit is the cutting tool that is used to create the V-shaped groove.

- The spindle is the rotating shaft to which the V-bit is attached.

- The table is the flat surface on which the workpiece is mounted.

V grooving machines can be used for a variety of materials, including wood, plastic, metal, and even glass. With the right v bit, they can also be used to engrave text and patterns into surfaces. Here’s a video showing how a V grooving machine works!

3. 3 Types of V Grooving Machines and Its Cost

If you’re looking for a cardboard grooving machine for box making, you’ll have a few different options to choose from. Here are three of the most popular types of v grooving machines and their approximate cost:

#1 Manual V Grooving Machine

This type of machine is operated manually and is ideal for small projects or those who are just starting out with v grooving. A manual grooving machine typically costs around $500 – $1000

#2 CNC V Grooving Machine

CNC v grooving machines are operated via computer numerical control and are ideal for larger projects or those that need precise cuts. A CNC v grooving machine typically costs around $5000 – $10000.

#3 Automatic V Grooving Machine

This type of machine is fully automated and is ideal for high-volume production. An automatic v grooving machine typically costs around $25000 – $35000

4. How to Choose the Right V Grooving Machine for Your Needs?

There are many different types of V grooving machines on the market, and choosing the right one for your needs can be a challenge. Here are a few things to keep in mind when making your decision:

Consider the Size of the V Grooving Machine

If you are planning on processing large sheets of cardboard for your business, you will need a machine that is capable of handling the size.

Consider the Material Thickness

Some V grooving machines are only designed to work with thin materials, while others can accommodate thicker materials. Be sure to check the specs of the machine before making your purchase.

Consider the Speed of the Machine

If your business will be working with V grooves on a production basis, you will need a machine that can produce the cuts quickly and efficiently.

Consider the Price of the Machine

V grooving machines can vary significantly in price, so be sure to set a budget before you start shopping. Fully automatic cardboard machines are usually much more expensive when compared to semi-automatic or manual cardboard machines.

By considering these factors, you can narrow down the field of V grooving machines and find the one that is best suited for your needs.

5. Where to Buy a High-Quality v Grooving Machine at An Affordable Price in China?

If you’re looking for a high-quality V grooving machine for cardboard, there are a few different places you can check.

Alibaba

Alibaba is a good option, as it is an online marketplace that connects buyers and sellers from all over the world.

Made-in-China

This platform is similar to Alibaba, but it is specifically for Chinese manufacturers and suppliers. Manufacturers here offer a wide range of products at a very competitive price.

Taobao

Taobao is another popular online marketplace in China, and it offers a wide variety of products from different sellers. You can find some great deals on v grooving machines here.

DHGate

DHGate is a wholesale marketplace that offers products at a discounted price. You can find some great deals on v grooving machines here, but be sure to check the seller’s feedback before making your purchase as some sellers may not be reputable.

6. 6 Tips on How to Ensure You Get Good Quality Machinery

When looking for a V grooving machine for cardboard, you want to be sure that you’re getting a high-quality machine that will last. Here are six tips on how to ensure you get a good quality V grooving machine:

#1 Check the Reviews

Search and see what others have said about the V grooving machine you’re considering. Make sure that it has good reviews and that people have been happy with its performance.

#2 Compare Prices

Don’t necessarily go with the cheapest V grooving machine, but compare prices to be sure you’re getting a good deal.

#3 Consider the Warranty

A V grooving machine with a good warranty is likely to be of better quality than one without a warranty.

#4 Go for Reputable Manufacturers

Buy from a reputable store or online retailer. Make sure you’re buying from a company that is known for selling high-quality products.

#5 Be Familiar with the Instructions

Read the instructions carefully. Once you’ve received your v grooving machine, read the instructions carefully so that you know how to use it properly and don’t damage it.

#6 Keep Proper Maintenance Scheduling

Follow the maintenance schedule. Be sure to follow the maintenance schedule for your V grooving machine so that it stays in good condition and lasts as long as possible.

By following these tips, you can be sure that you’re getting a high-quality V grooving machine for cardboard.

7. Safety Checklist Before Using a V Grooving Machine

Before using a V grooving machine for cardboard, it is important to go through a safety checklist to ensure that the machine is properly set up and that you are familiar with its operation.

Ensure the Good Condition of the MachineCheck that the V-blade is sharp and in good condition. If the blade is dull or damaged, it could cause the machine to jam or otherwise operate improperly.

Secure the Machine Properly

Make sure that the V-grooving machine is properly secured to a work surface. If the machine is not securely fastened, it could easily tip over during use.

Check the Calibration and Safety Features of the Machine

Make sure that the machine is properly calibrated and that all safety guards are in place. This includes calibrating the gluing machine and folding boxes.

Allot for Standby Staff in Case of Emergencies

Always have someone else in the room when you’re using the V grooving machine, in case of an accident. Standby staff should undergo proper training and be provided briefing regarding factory safety practices.

Review the Operation Manual

Allow for a few minutes to let your employees review the operation manual before starting the V-grooving process.

By following these simple safety precautions, you can help ensure a successful V-grooving experience.

8. 5 Buying Tips About V Grooving Machine You Shouldn’t Miss

When you’re ready to buy a V grooving machine, there are a few things you should keep in mind. Here are five buying tips to help you make the best decision for your needs:

| #1 Size | The first is the size of the V-groove. You’ll want to make sure the machine can accommodate the size of V-groove you need. |

| #2 Depth | The second factor is the depth of the V-groove. Again, you’ll want to make sure the machine can accommodate the depth you need. These machines can usually accommodate depths up to 12 inches. |

| #3 Speed | The third factor is the speed of the V-grooving process. Some machines are faster than others, and you’ll want to make sure you choose a machine that can V-groove at the speed you need. |

| #4 Capacity | The fourth factor is the capacity of the V-grooving machine. That is, how many sheets of cardboard can the machine V-groove at one time? V grooving machines can accommodate up to 500 sheets at a time. |

| #5 Installation | The machine has an electrical connected load that must be considered when planning the factory installation. |

9. Conclusion

So, whether you’re a hobbyist or a professional cardboard craftsman, we hope this guide has helped you find the perfect V grooving machine for your needs.

If you have any questions about the machines we’ve featured or would like to recommend one that we missed, don’t hesitate to contact us at Autoboxup. We are always happy to help out!