The operation line is an important element in the structural design of the carton folding machine! For the box body design of the tubular carton folding machine, the bottom design of the non-tube non-disc or partial disc carton folding machine, according to the box type !

If the forming line cannot be used as the working line !

A new line needs to be redesigned, and the working line will affect the design of the relevant parts of the carton such as the box cover ” box bottom ” or the partition wall structure.

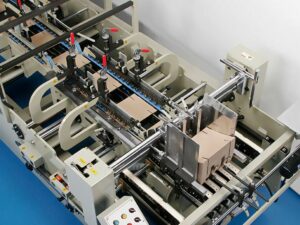

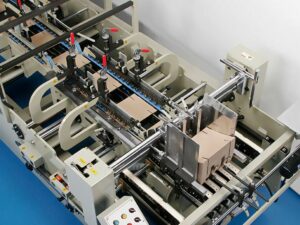

1. Production Line for Tubular Carton Folding Machines

Production line for tubular carton folding machines

Because the box joints of the tubular carton folding machine are joined in a flat state, and this flat state goes through counting, stacking, packing, storage, transportation and other links until the box body is supported before the contents are packaged on the automatic packaging line. Open, so the design of the working line is an important element of the box design.

According to the above requirements, the operation line should be designed in the longitudinal direction of the box body in the plane expansion diagram of the tubular carton folding machine. When a pair of operation lines are folded, the corresponding positions at both ends of the blank

The positions should coincide, that is, points A and E coincide, and points A 1 and E 1 coincide.

Using the molding line to design the operation line

Using the molding line to design the operation line

The 4 kinds of tubular carton folding machine bodies shown in Fig . 2 . Their working lines are B 1 B and DD 1. When they are folded flat along these 2 working lines, points A and E coincide, and points A 1 and E 1 coincide . Because the BB 1 and DD 1 lines play the role of folding and forming in a three-dimensional state, the forming line and the operating line are the same line.

The box-type operation line shown in Figure 3a is AA 1 and CC 1 , so that when the bonding surfaces U 1 UTT 1 , S 1 SAA 1 and the corresponding positions are bonded in flat form, the number of flat folds is the least ( 2 times). If BB 1 and DD 1 are still selected as before , three flat folds are required. At this time, SS 1 is added as the operation line, which will inevitably increase the difficulty of mechanical forming. As shown in Figure 3b , there are 4 box body production lines . First, SS 1 is folded flat, plane V 1 VSS 1 coincides with plane S 1 SCC 1 , then UU 1 and BB 1 are folded flat together, and finally DD 1 is folded flat to complete joint bonding. synthetic type. The operation lines of the box type shown in Figure 2 and Figure 3 all play a forming role when they are folded into a three-dimensional shape. This type of box type is an even-numbered prism or an even-numbered regular prism, so its operation line is the forming line . The deformed even-numbered prism carton folding machine line shown in Figure 4 is also a forming line.

2. Design a New Line as an Operation Line

For the odd-numbered prism box type shown in Figure 5 , problems such as flat-shaped adhesive joints and flat-shaped transportation stacking must also be considered, so two working lines CC 1 and AA 1 should also be designed , of which CC 1 is in the folded three-dimensional It plays the role of forming, but AA 1 does not play the role of forming.

It is a purely working indentation line, that is, a new design line. For some special-shaped carton folding machines, the forming and folding lines cannot make the two ends of the blanks align and coincide after being flat-folded. At this time, two vertical operation lines must be redesigned, and the operation lines should be extended to pass through the cover (flap) as the case may be. ) or bottom plate (flaps), such as BF 1 line and DG 1 line in Figure 6 a , FF 1 line and GG 1 line in Figure 6 b .

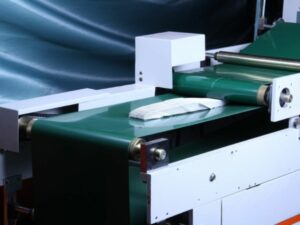

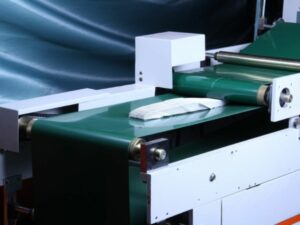

The type characteristics and manufacturing techniques are different from other box types. An important step in the forming of the box is that the two ends of the box bottom and the two sides of the box body are bonded in a flat state, which requires a central horizontal indentation line at the bottom of the box bottom, which can make the bottom of the box It is formed automatically during use, so it is a working line as shown in Figure 7 .

3. Multi-Wall Tray Type Carton Folding Machine Production Line

Figure 8 shows a multi-wall disc carton folding machine. In order to ensure that the joints on both sides of the box are bonded in a flat state, it is also necessary to design a horizontal line ef at the bottom of the box to ensure that the box is flat during transportation and automatically formed during use.

4. The Influence of the Operation Line on the Structure of the Carton

ince the operation line is the main box-shaped element, it has an important impact on the structure of the carton. Once the design of the operation line is completed, the design of the box body and internal structure is determined. In Fig. 9a , the operation line is designed as lines B and D , which determines that when the partition board is restored to its original shape from the three-dimensional to the flat plate, it must be dumped in the direction of C. Therefore, the direction of the joint of the box-type partition wall is consistent with the direction of the joint of the box body.

Fig. 9b , the working line is designed as lines A and C , which determines that when the partition board returns to its original flat shape, the partition board on the extension plate of the front plate must be dumped in the direction D , and the partition board on the extension board of the middle partition must be tilted in the direction S dump.

Therefore, the direction of the joint of the box-type partition wall is opposite to the direction of the joint of the box body. In Fig . 9c , the working line is designed as A and C lines, because the partition boards are all on the extension board of the middle partition board, thus it is determined that when the partition board returns to a flat shape, the partition board bonded to the rear board must be dumped in the S direction , Partition panels glued to the front panel must be poured in the T direction. Therefore, the direction of the joint of the box-type partition wall, one group is opposite to the direction of the box body joint, and one group is then the same.

| Operation Line Stage |

Influence on Carton Structure |

| Design |

Determines the size, shape, and functionality of the carton. Influences how it will be used and how products will fit inside. |

| Cutting |

Accuracy at this stage ensures sharp edges, precise dimensions, and a consistent look and feel. Improper cutting can weaken the carton or make it less functional. |

| Folding |

Determines the carton’s 3D shape and strength. Incorrect folding can lead to weak points, misalignments, or aesthetic imperfections. |

| Gluing |

Holds the carton in its 3D form. Weak or inaccurate gluing can result in a carton that falls apart or doesn’t hold its intended contents securely. |

| Printing |

Adds branding, instructions, or other information to the carton. While this doesn’t influence the physical structure, it impacts the visual appeal and user experience. |

5. Epilogue

The operation line plays an important role in the carton forming process, because the operation line can also ensure that the carton can be folded into a flat shape for transportation after forming. After reaching the carton automatic packaging production line, as long as the box opening mechanism opens the box body , the carton box body is automatically formed. Therefore, the design of the operation line is an important design element in the structural design of the carton folding machine.

If the forming line design cannot be used for the tubular carton folding machine production line, one or several pure working creasing lines must be designed according to the box body structure.

When other types of box structures are needed, the operation line can be designed at the bottom of the box.

The working line will affect the structural design of the relevant parts of the carton.